Ringele AG

The Swiss company Ringele AG processes sheet metal for highly complex system solutions in small and medium batch sizes of unique quality. The company relies on the use of cutting-edge technologies and a consistent implementation of the LEAN philosophy.

Company headquarters

Pratteln

Industry

Sheet metal processing

Products

Sterilisation cassettes, covers, holders, housings, machine frames, valve housings, implants

Applications

Medical technology, automation, aviation industry, rail transport technology, measurement and control technology, semiconductor industry

Competences

Development and production of sheet metal components and systems with an extraordinary vertical range of manufacture for small and medium batch sizes, LEAN, laser welding, forming, folding, punching, electropolishing

Since

1927

Internet

www.ringele.ch

Portrait

Solutions in sheet metal

Ringele AG is a technology-driven company that manufactures highly complex products and systems from sheet metal for a wide range of applications in various industries. These include medical technology, automation, measurement and semiconductor technology. Approximately 200 employees work at the Pratteln site in Switzerland. Modern, cutting-edge technology is used to apply a wide range of high-precision and efficient manufacturing processes.

As a technology leader, Ringele AG achieves a very high level of vertical integration. The aim is to offer customers highly complex solutions in sheet metal from a single source as a so-called "one-stop shop". In conjunction with consistent implementation of the LEAN philosophy, this leads to highly optimised and efficient production. This enables the company to secure global competitiveness at its Swiss location and fulfil the essential customer promise: Solutions in sheet metal for demanding applications in unique quality.

Sheet metal is very flexible to use and process. It is a forward-looking material that requires less energy in production and processing compared to metal-cutting work, minimises waste, and in this way enables more energy-optimised production. The production steps require a great deal of experience and craftsmanship.

Foundation during the crisis

The company is founded in 1927, when the Great Depression of the late 1920s and 1930s was already casting its shadow, and two craftsmen, Hermann Zanker and Hans Ringele, who have just become unemployed, decide to manufacture metal goods and arts and crafts products on their own account. The founding location is a 50 m2 workshop with considerably modest machinery at Hohlen Gasse 12, in Binningen.

At the beginning of the Second World War, the company employs four more people. Due to wartime regulations, only sheet steel and light metal are processed, and the product range shifts from arts and crafts to technical needs. After the sudden death of partner Hermann Zanker, the company continues under the name Ringele+Co.

In 1961, the company is converted into a limited partnership (today's Ringele AG). The company moves to Bottmingen, employs more than 60 people, and earns a good reputation at home and abroad with its "principle of quality work".

In 1995, Ringele AG, now with 78 employees, is taken over by Andreas Zurbrügg and Urs Leuenberger as part of a succession plan. The managers invest in machinery, push ahead with important industrial certifications, and start expanding into new industries, e.g., medical and semiconductor technology. The LEAN philosophy begins to be consistently implemented in production and administration, in a 15-year process. The company continues to invest in further automation of production.

Fast-forward to today: The first fully automated lines have been put into operation, enabling round-the-clock production. Ringele AG also integrates special processes into its own production in order to act as independently as possible from suppliers and thereby keep its promise of quality as a one-stop shop.

Application

Ringele manufactures the products that other competitors cannot. With this self-image, Ringele AG handles highly complex orders in annual batch sizes of one to 30,000 units. Solutions are developed in close cooperation with customers. In the process, Ringele brings its unique know-how and great tenacity to bear in the search for the most suitable material and optimised production.

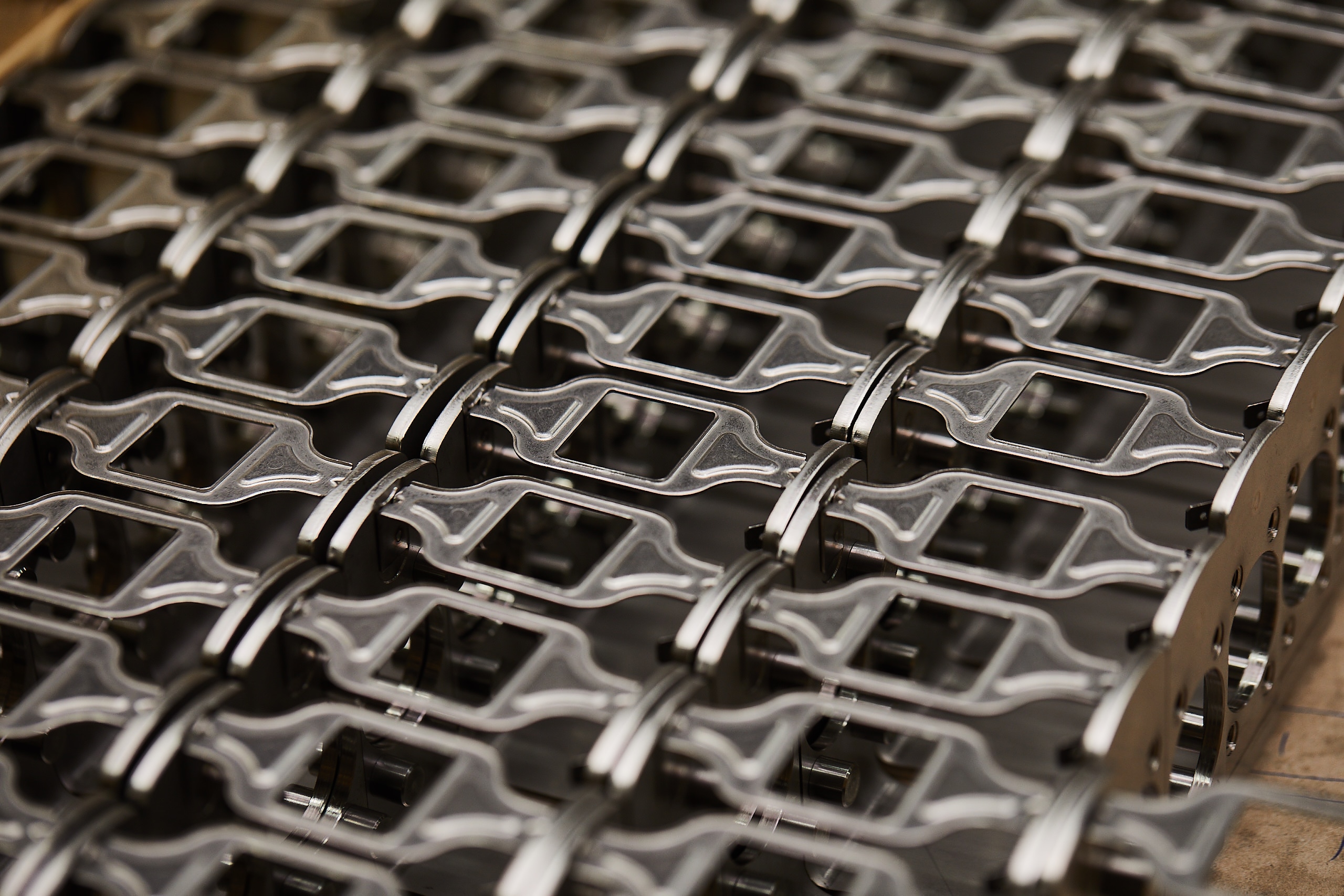

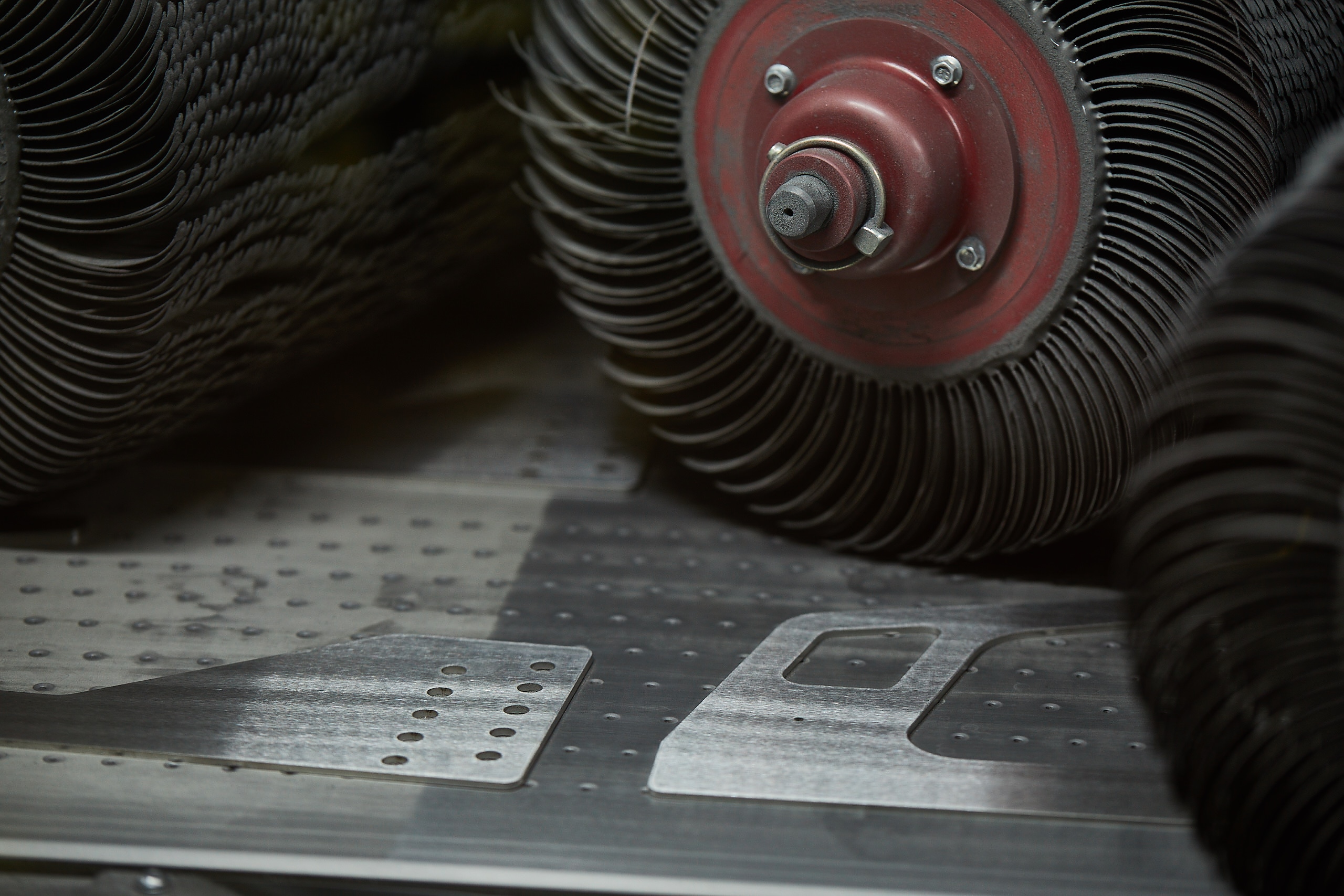

The company gained a high reputation on the market with its persistence to develop process-safe solutions in production. One example of this is sterilisation cassettes. These containers are used to store medical/surgical instruments. They consist of perforated and bent sheets designed to be used in a highly sterile environment, which places high demands on the material and the shape: The containers must be easy to clean and resistant to the high temperatures in sterilisation. The sheets are stamped, formed, welded, electropolished, and assembled. The electrochemical process of electropolishing is perfectly suited for surfaces that are easy to clean and, if possible, must not have any rough spots. This is particularly important for applications in medical technology, as it reduces the possibilities for germs to adhere.

Another product is a machine frame for automation in cable processing with very complex installations. For this frame, sheet metal is folded, welded, bent, coated, and assembled with electronic components to very tight tolerances.

Source: Ringele intern

Markets

Ringele AG mainly serves the Swiss market. Its customers are medium-sized companies and multinationals with global sales markets, which means that many Ringele AG products find their way abroad. Ringele AG also has customers in Germany and Austria. The growth strategy focuses primarily on customers in German-speaking Europe. There is still considerable potential here through expansion into new industries and sectors, as well as consistent efforts to acquire new customers.

Insights

Every company and each employee are unique and have a distinct history. The following texts offer an impression of the motivation, perspective and convictions of the people behind the stories.